Downhole Completion

Well completion is a critical process requiring specialized expertise and reliable equipment. Our services encompass all aspects, from preparing the well bore to installing down hole equipment and executing perforating and stimulation treatments. We offer a comprehensive range of high-quality, durable products designed to enhance efficiency and reliability in both onshore and offshore environments.

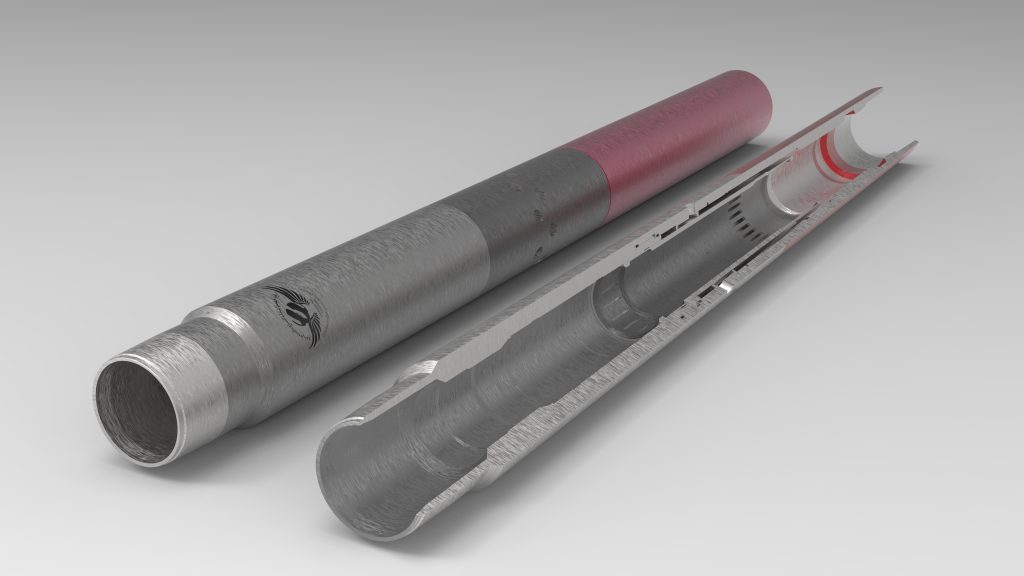

Downhole Safety Valve (DHSV): Prevent Well Blowouts and Control Fluid Flow

Our DHSV automatically shuts in wells during emergencies (e.g., wellhead fire, pipeline rupture, blowout) by cutting the umbilical HP line or destroying the wellhead/tree. This surface-controlled, subsurface safety valve allows for normal fluid flow but forms a hydrocarbon flow barrier when closed, enabling well kill operations. Available in 4-1/2″ to 7″ sizes and 5000-10000 psi working pressure.

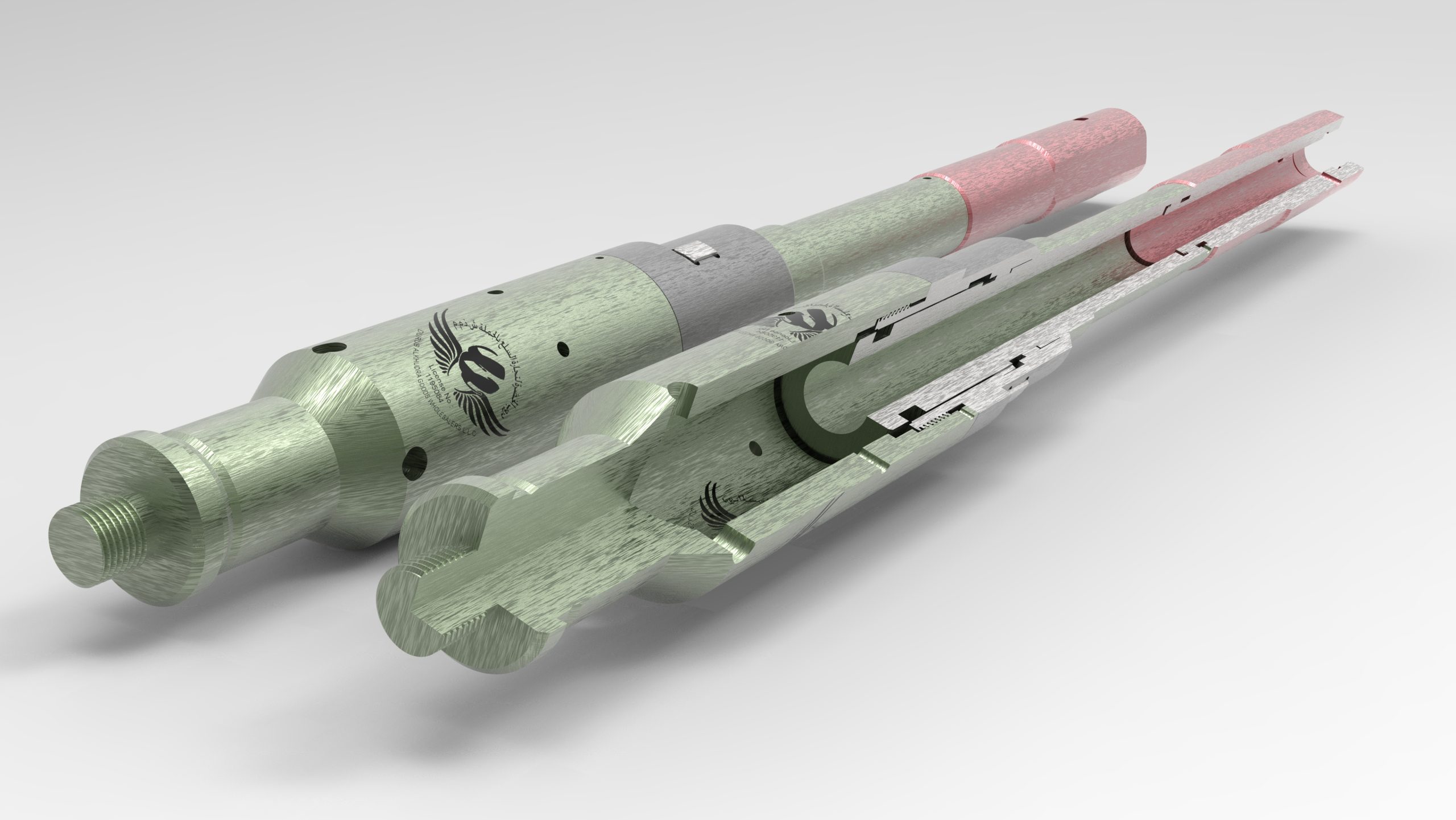

Production Packers: Reliable Zone Isolation and Enhanced Well Production

The production packer is a crucial downhole tool in the production string, providing essential zone isolation and protecting the casing. Its primary function is to create a reliable seal between the tubing and casing, preventing fluid migration and enabling effective control over your valuable asset.

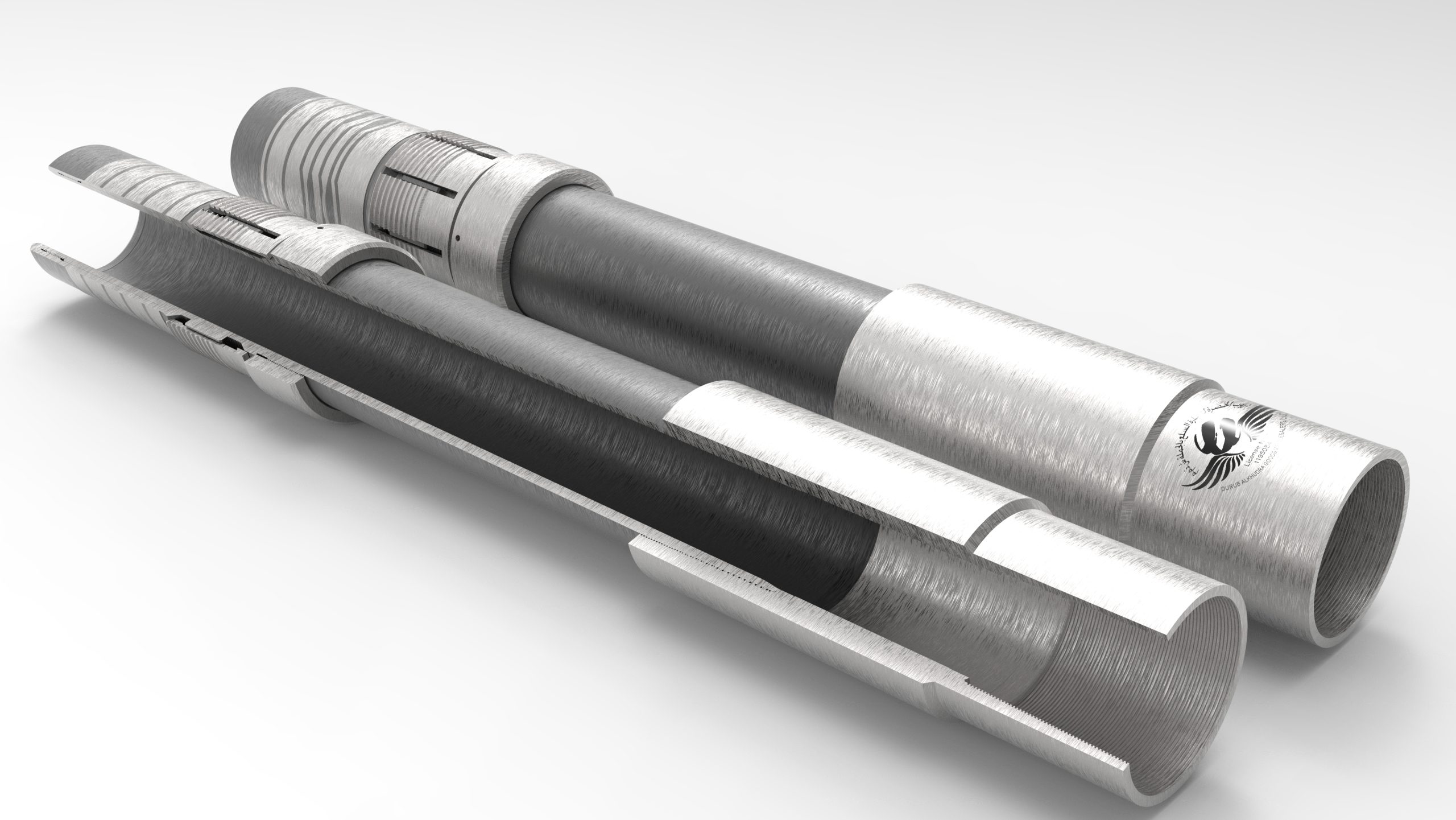

Traveling Joints and Expansion Joints: Accommodate Tubing Movement

Ensure smooth well operations with our durable traveling joints and expansion joints. Designed to accommodate tubing movement due to temperature and pressure changes.

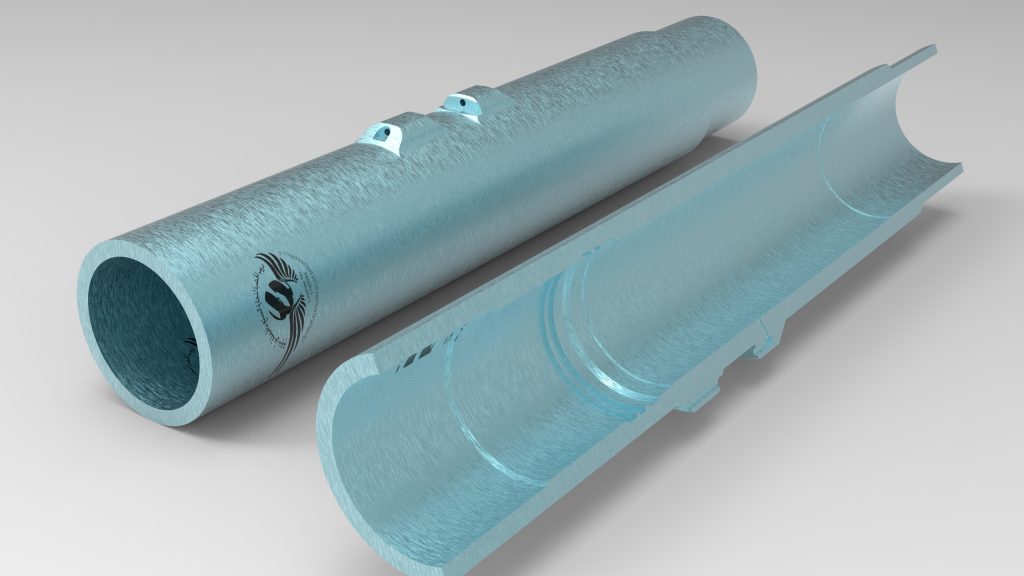

Flow Couplings: Mitigate Erosion and Extend the Life of Your Well Components

Flow couplings are specialized pipe components designed to reduce erosion and extend the lifespan of production tubing and completion equipment. By increasing the internal diameter while maintaining compatibility with standard tubing, flow couplings minimize the effects of turbulent flow.

Improve Well Control with Sliding Side Door Technology

A versatile valve for tubing and annulus communication. Mechanically or hydraulically operated, it’s installed within the main tubing string and allows for open, equalizing, or closed positions using slick line or coiled tubing tools. Multiple sleeves can be run in a single string.

Mule Shoes: Streamline Wireline Operations with Secure Re-Entry Guidance

Ensure smooth and efficient wireline operations with our reliable mule shoes. Designed for easy tool re-entry and reduced downtime.

Perforated Tubing Joints: Enhance Oil and Gas Well Production with Optimized Fluid Flow

Maximize oil and gas production with our perforated tubing joints. Designed for unrestricted fluid flow and improved reservoir access.

Landing Nipples: Secure Wireline Flow Control in Oil and Gas Production

Landing nipples are downhole tubing nipples used to position wireline flow control devices within the production string. Common types include No-Go, Selective-Landing, and Ported Safety Valve nipples, all maintaining consistent packing bore ID for a given tubing size and weight. Strategically placed in completions, they facilitate the installation of flow control devices like plugs and chokes.

Wireline Tools and Downhole Accessories: Essential Equipment for Oil and Gas Well Operations

Our comprehensive range of wireline tools and downhole accessories are essential for efficient and safe operations throughout the entire well lifecycle, from drilling and completion to production. These specialized devices are designed for deployment and retrieval within wells using a wireline or flexible cable.