Explore Our Featured Liner Hanger Products

Durub Company provides comprehensive liner hanger solutions for diverse well environments and casing structures. Our range includes single and double cone designs, hydraulic and mechanical setting options, and various rotating/non-rotating and slip configurations. Available in sizes from 3-1/2″ to 16″, we offer a wide selection of materials (L80, L80 9Cr, L80 13Cr, T95, C110, P110, Q125) all manufactured and tested to API 19LH standards.

Liner Hangers

Durub Liner hangers suspend the liner within your existing casing string. These hydraulic-set systems offer options for ultra-high hanging capacity, high bypass, and rotation while cementing.

Top Packer

The Liner Top Packer seals the liner annulus, withstanding 5000 psi. Its one-piece sealing element ensures high-integrity, and optional hold-down slips prevent liner movement. A polished bore receptacle simplifies liner entry.

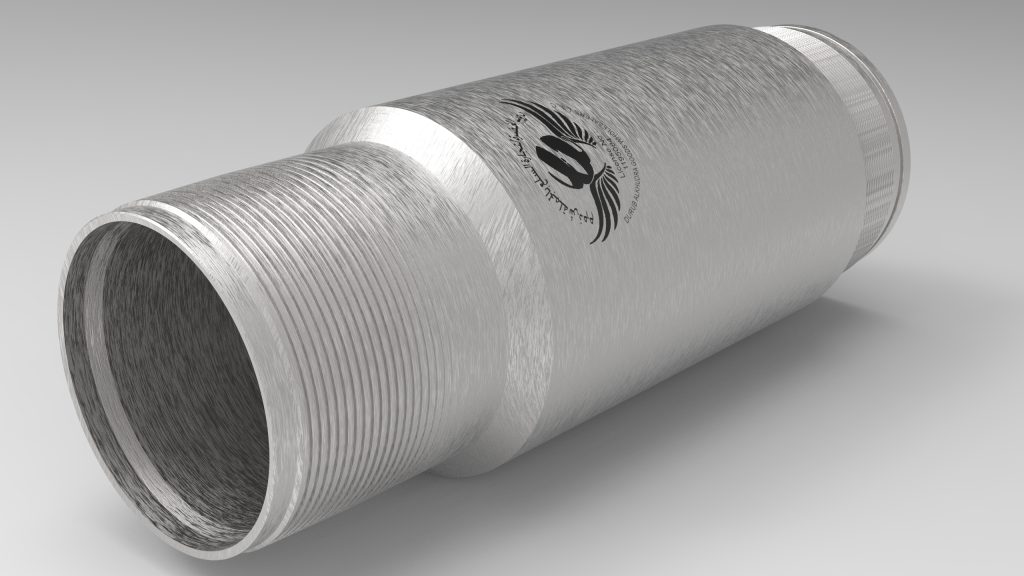

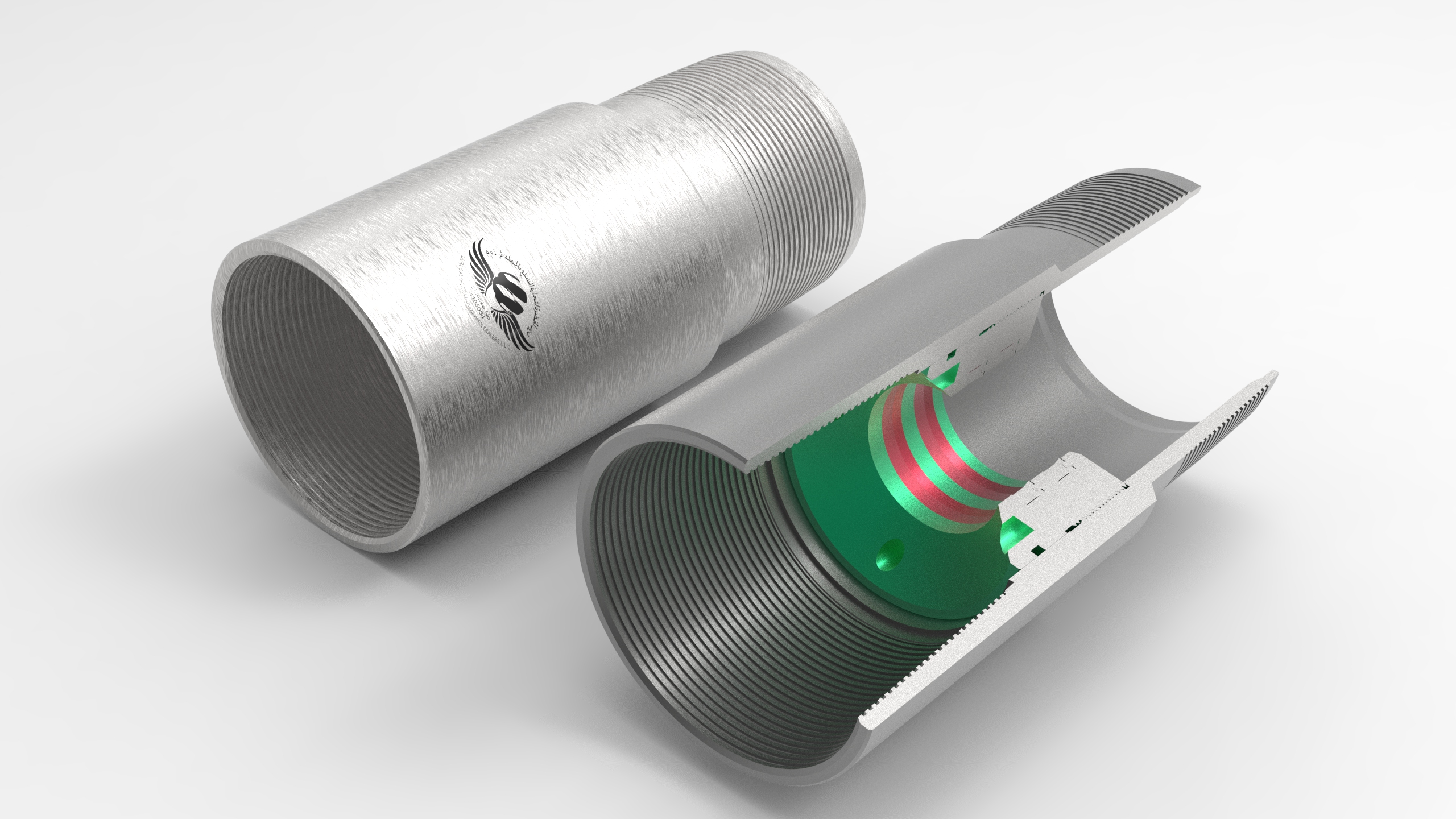

Polished Bore Receptacle (PBR)

The Polished Bore Receptacle (PBR) increases liner ID for easier tieback seal nipple installation. Available in 6-15 ft lengths.

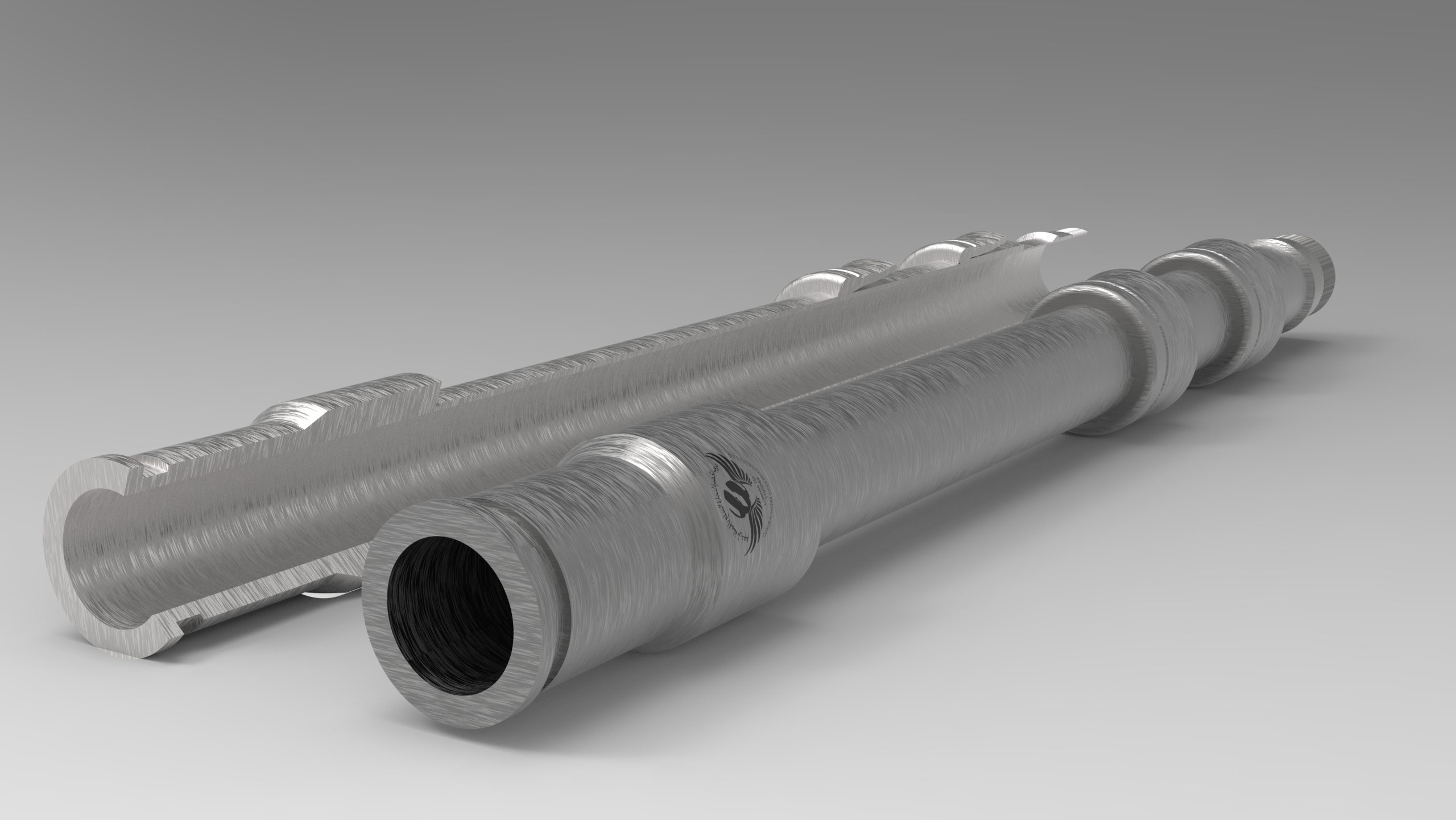

Setting collar

The setting collar, run above the liner hanger, supports the liner’s weight and engages the mechanical or hydraulic setting tool during running. It connects to the setting tool via eight round threads; this connection uses a left-hand Acme thread for mechanical tools or a groove for hydraulic tools.

Landing Collar (LDC)

LDC: Pressure-maintaining stopper plate above float collar (or shoe). Features shearable ball seat (1000 psi) and anti-rotation profile.

Pack Off-Bushing (POB)

The pack-off bushing (POB) seals the slick joint and liner during circulation or cementing operations. Its primary function is to maintain the pressure needed for setting the hydraulic hanger and shearing the landing collar. Drillable and retrievable POBs are used in different operations.

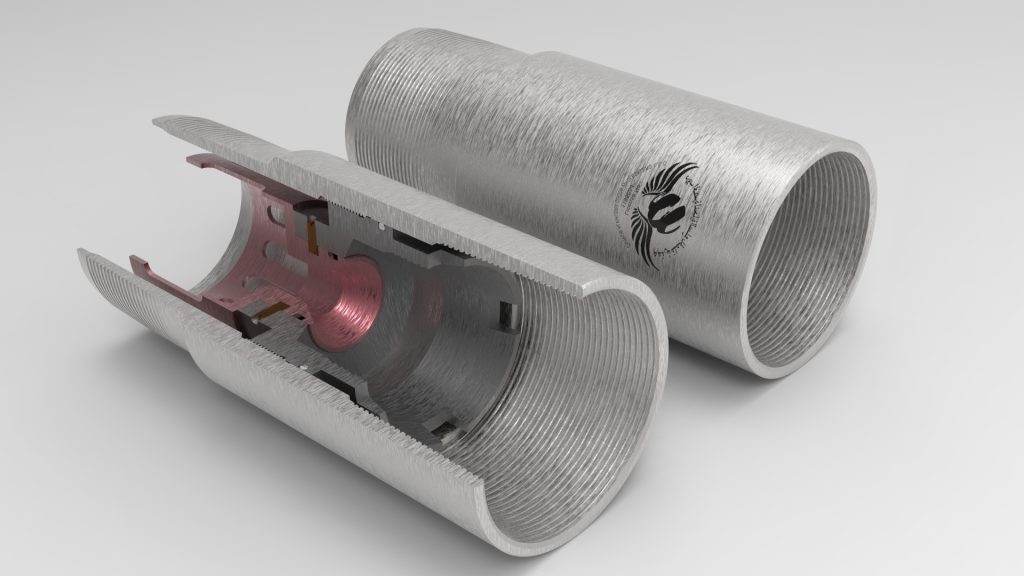

Float collar

The float collar, a one-way valve positioned one or two joints above the float shoe, prevents cement backflow (U-tubing) using one or two aluminum check valves. These valves, incorporating a PDC-drillable plunger, spring, and aluminum rod, are tested according to API RP 10F.

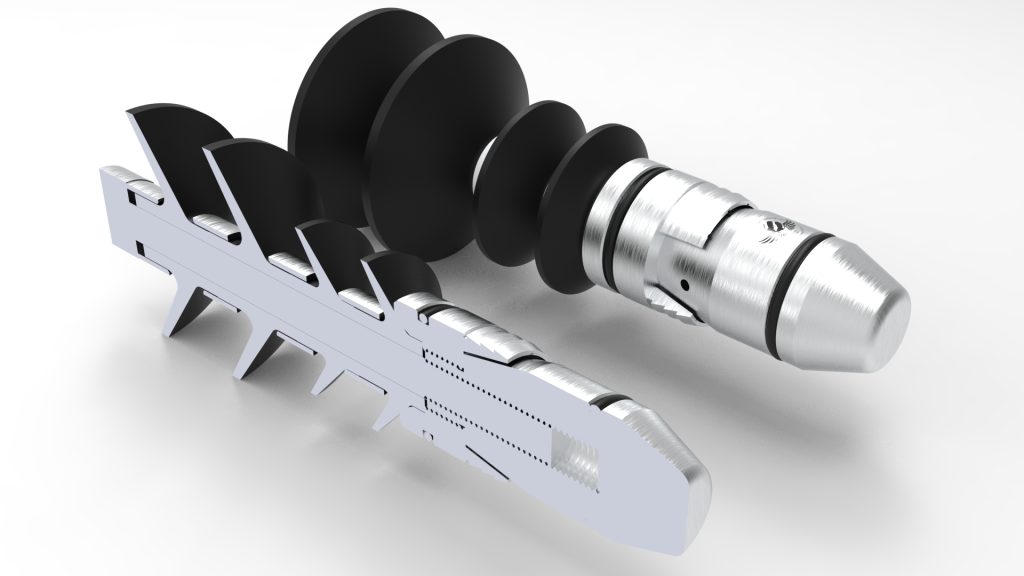

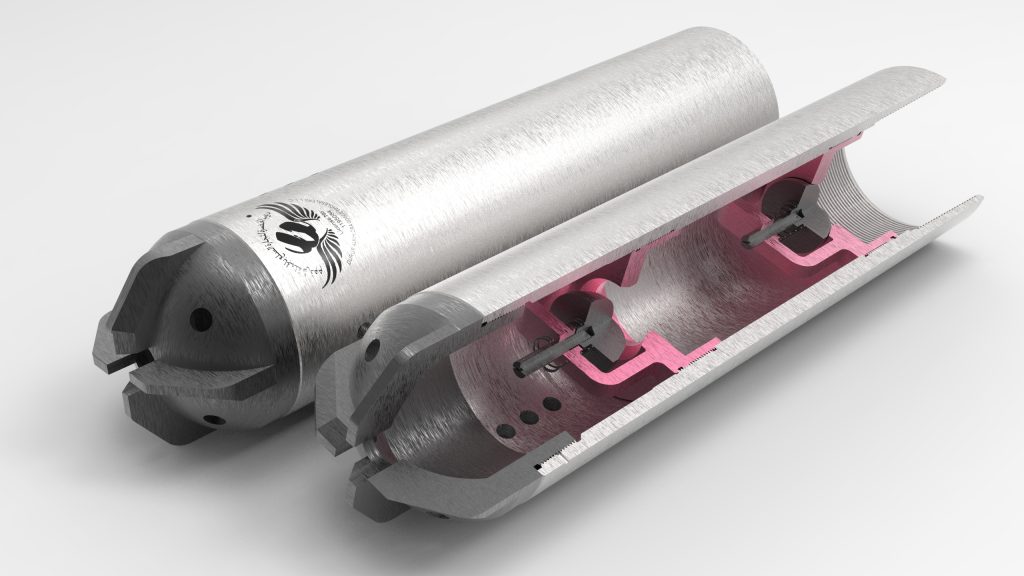

Float shoe

The float shoe guides the liner string smoothly into the well bore during lowering. Its body incorporates metal and tungsten carbide blades to efficiently ream and clean the hole. The internal, typically double-plunger, valves prevent fluid entry into the liner. Aluminum internal parts provide high strength and are PDC-drillable.

Wiper Plug

The liner wiper plug is connected to the slick joint with brass shear pins. After wiping the drill pipe, the pump-down plug latches onto the wiper plug. Increased fluid pressure shears the wiper plug from the slick joint, pushing the cement down and latching onto the landing collar (LDC). Once landed, the bumping pressure and latch mechanism prevent fluid backflow into the liner.

Pump down plug

The pump-down plug is positioned in the cement manifold before liner hanger operations. After cement pumping, releasing the plug separates the cement from the displacement fluid. It wipes cement from the drill pipe and connects to the liner wiper plug located below the setting tools and slick joint. Its aluminum and rubber body is easily milled by a PDC bit.